|

|

|

Research on energy materials for various next-generation energy devices |

|

|

|

|

|

FTFL has vigorously conducted research aiming at high energy density, high power density, safety, and lifespan improvement of various battery systems. To address the issue of severe capacity fading of Li-S battery, an ultrathin and functional polymer nanolayer is applied to the battery separator. The developed separator effectively captures soluble lithium polysulfides, mitigating the shuttling effect and extending the calendar life of Li-S batteries while maintaining their initial capacity, even with minor capacity decay. Furthermore, the iCVD process enables the passivation of highly reactive Li metal without causing any surface damage. By introducing an electrolyte-swollen polymer scaffold, Li ion transport is facilitated, and native solid-electrolyte interphase nanolayers are reinforced with the hybridization of iCVD polymer, prolonging the duration of cycling operation in practical Li-metal battery by 600% compared to pristine Li metal.

|

|

Triboelectric nanogenerators (TENG) have emerged as sustainable power sources owing to their simple structure, fabrication, low cost, and excellent output. The TENG converts mechanical energy into electrical energy based on contact electrification and electrostatic induction based on pairs consisting of different electron affinity. Since iCVD has advantage on creating layers on arbitrary substrates, it has promising effect by applying on textile to elastomer, which is known to be difficult to create layers on due to low wettability of its material

|

|

Separation processes are instrumental in high energy efficiency and environmental sustainability. They have a close connection to various aspects of everyday life, ranging from obtaining pure water and clean air to producing high-value petrochemicals, pharmaceuticals, and bio-refineries, along with responding to climate change. FTFL concentrates on feasible solutions for effective separation processes through various functional materials and structural design, and which can allow for facile modification on many separating membranes, including porous carbon materials and hollow fibers. Ongoing in-depth works are pursuing a range of research involving oil/water, microalgae, CO2 separation, organic solvent nanofiltration, and PSA applications.

| |

|

|

|

|

|

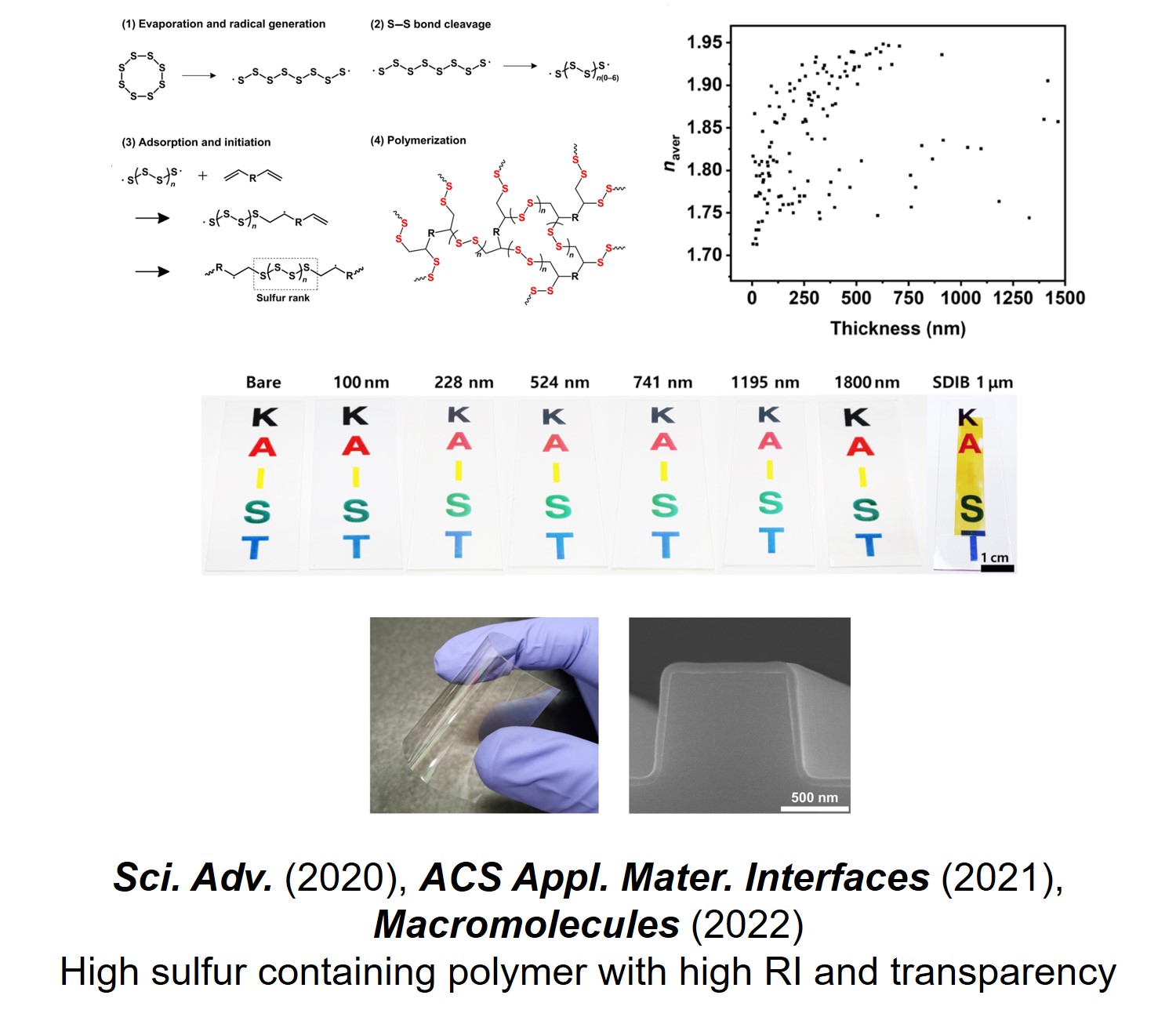

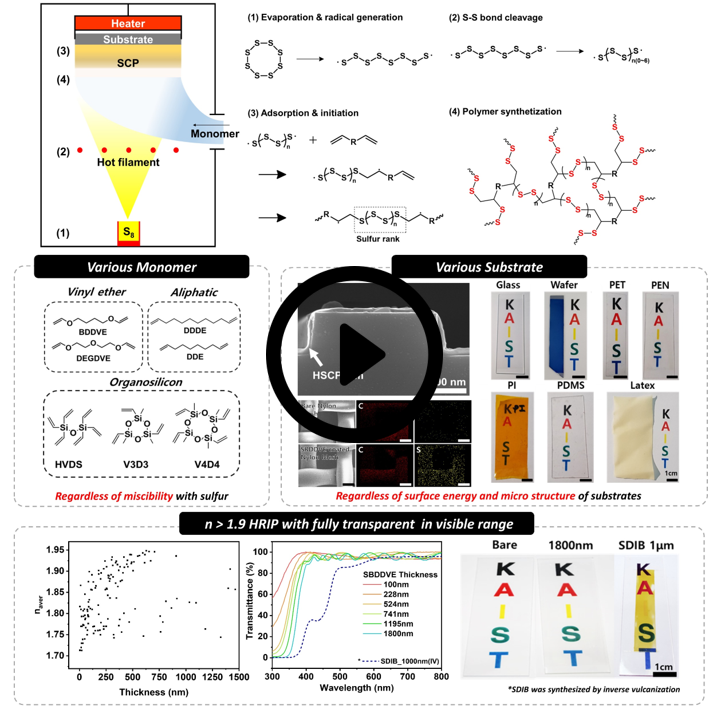

On the other hand, FTFL devised a novel vapor phase process, named by sulfur Chemical Vapor Deposition (sCVD). With its sulfur polymer library, it is applicable to high performance optoelectronic devices. Unlike from conventional synthesis processes, sulfur polymer films fabricated through sCVD process indicated high transparency in the region of visible light. In addition to excess sulfur content, unprecedented refractive index of 1.97 comparable to inorganics could be achieved, which also showed excellent mechanical flexibility under thousands of bending. Moreover, by controlling process parameters, FTFL developed a series of sulfur-containing polymers with enhanced thermal stability with glass transition temperature of 110 ℃. This study will pave the new way for future-oriented optoelectronics on account of these advantage.

| |

| Please click on the image to watch the video clip |

|

|

|

| |

|

|

| Lithium metal battery |

Separation process |

Sulfur chemical vapor deposition |

|

|

|

|

|

|

|