|

|

|

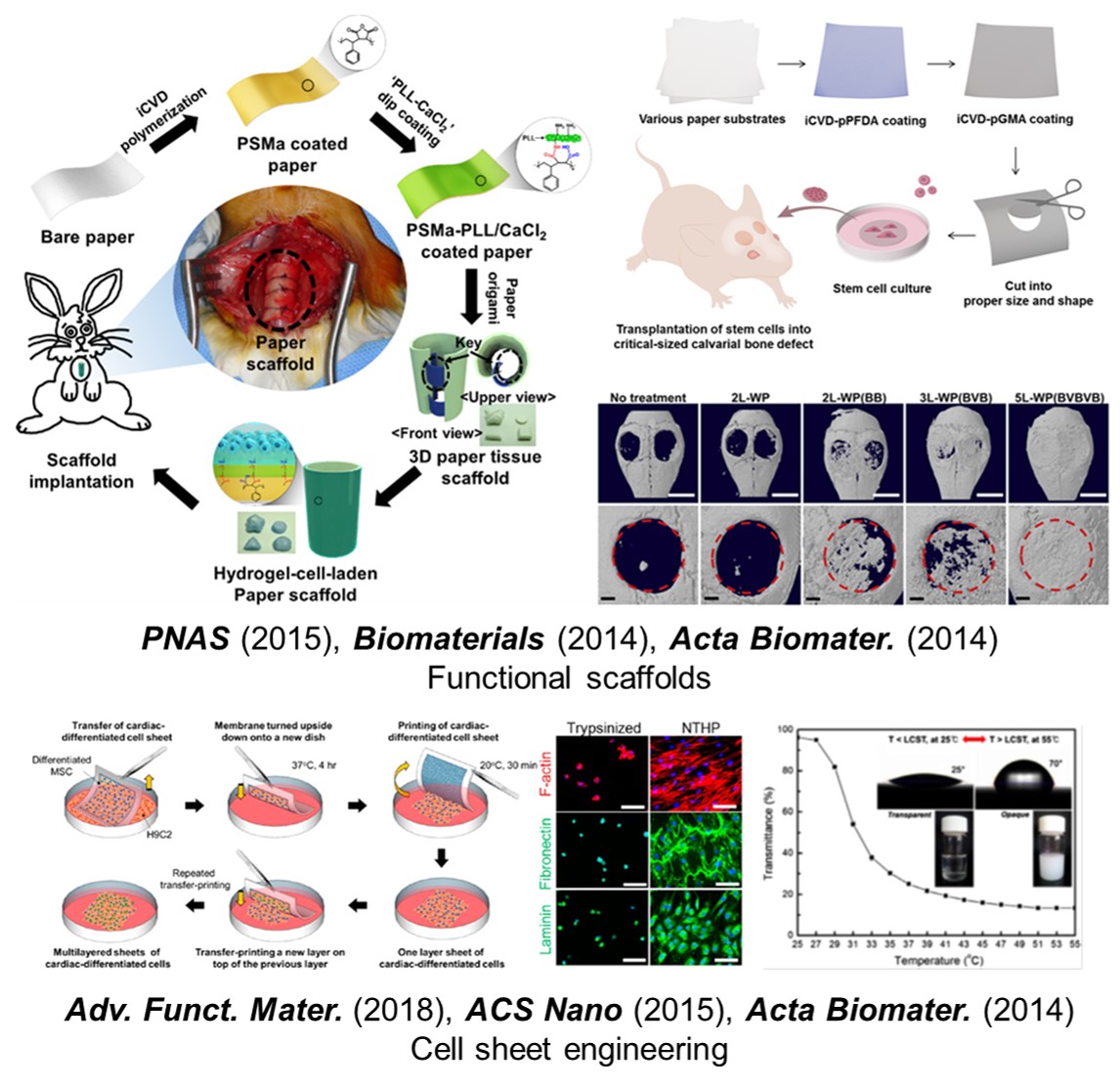

Biomaterials for tissue engineering

|

|

|

|

To date, the iCVD process can generate more than 60 kinds of functional polymer films. Considering the capability of iCVD process to form homogeneous copolymer films by combining more than two different monomer species, the number of monomer combinations that can be deposited is practically uncountable. Based on this iCVD technique, FTFL has devised numerous functional polymer films, as well as methods to develop various biomedical devices and modify their surfaces. For example, FTFL developed an ingenious method to bind cell-encapsulated hydrogel on the surface of the iCVD-modified paper substrate and constructed 3D cell culture scaffolds from 2D paper using simple origami method. Via this process, we fabricated a bone-regenerating tissue-scaffold and an origami-based synthetic trachea.

| |

|

|

|

|

FTFL also developed a nano-patterned substrate platform whose surface was able to immobilize osteo-inductive bone morphogenetic protein-2 (BMP-2) peptides. The effects of various biophysical and biochemical factors on stem cell differentiation were investigated. Bio-inspired, acetylcholine-like surface was devised for facilitated neuron cell culture, which enabled exceptionally long-term survival of primary neuronal cells for up to 90 days.

|

|

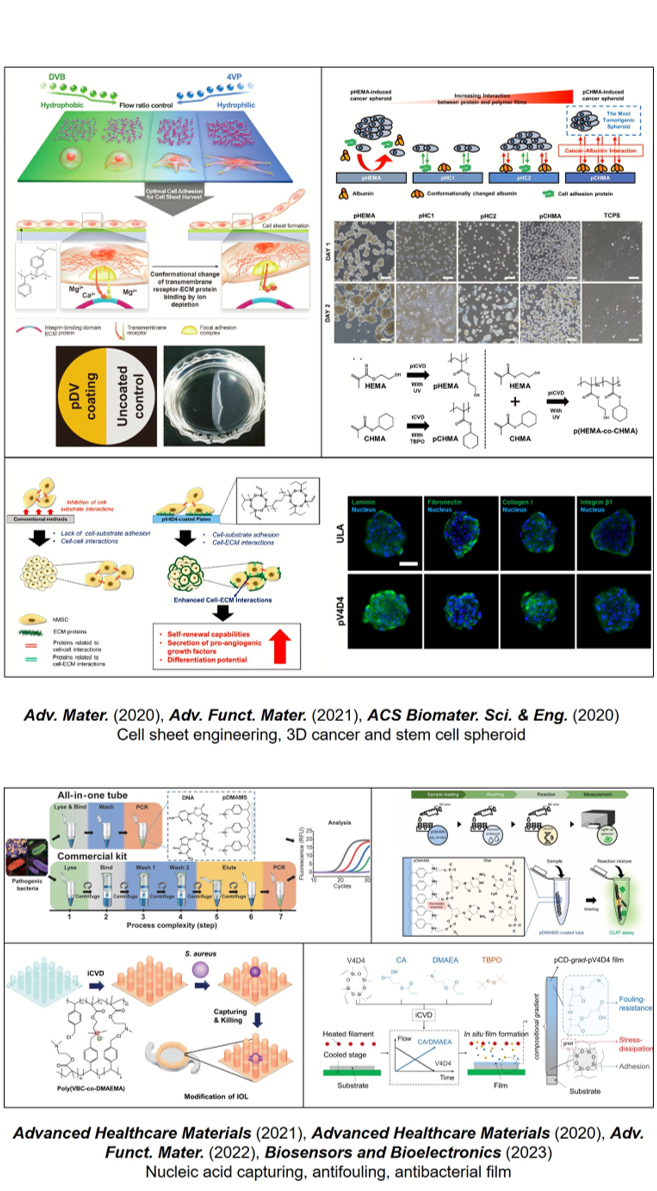

By controlling the surface free energy via copolymer of hydrophilic and hydrophobic polymers, we developed a cell sheet technology that can control the adhesion between the cell and the culture substrate. In addition, the cell culture surface made with the aid of the iCVD process was used for cancer spheroid and MSC spheroid research. We explored the interaction between the surface adhesive proteins and cancer spheroid by studying the changes cancer spheroids undergo on thin film cell culture surface of different surface energies. Furthermore, we confirmed that the interaction between MSCs and extracellular matrix (ECM) increased on the surface of hydrophobic polymer film cell culture platform.

Using iCVD technology, FTFL is also conducting a study on the diagnostic system's pre-processing process. In particular, we developed positively charged polymers containing a tertiary amine group, which can be coated on the inner wall of a PCR tube or microchip using iCVD to capture negatively charged nucleic acids. Through this development, PCR process was successfully reduced dramatically compared to the conventional PCR technology. In addition, we also developed the polyampholyte hydrophilic antifouling film by iCVD technology. Developing the stable hydrophilic antifouling film was one of the difficult problems. However, it is possible to introduce a compositional gradient structure using two or more monomers via iCVD, and it has succeeded in developing a long-term, stable, stretchable non-fouling hydrophilic film. In addition, research has been conducted to improve the performance with antibacterial coating on the nanopillar array.

| |

|

| Please click on the image to watch the video clip |

|

|

|

|

| Cell sheet formation |

3D cancer spheroid formation |

All-in-one PCR for nucleic acid extraction |

|

|

|

|

|

|

|