|

|

|

|

|

(1) Advanced interphase engineering for next-generation lithium batteries

FTFL vigorously sets research objectives to achieve high energy density, high power density, safety, and extended cycle life across various battery components and systems.To address instability and dendrite growth in lithium metal batteries, we apply functional polymer nanolayers onto anode surfaces using iCVD technology. This process enables the passivation of highly reactive Li metal without surface damage. By introducing electrolyte-swollen polymer scaffolds, lithium-ion transport is facilitated while the native SEI is reinforced through hybridization with the iCVD polymer. As a result, practical lithium metal batteries achieve up to a 600% improvement in cycling stability compared to pristine Li-metal. In all-solid-state batteries, polar functional polymer coatings are strategically applied to metal anodes (In) to prevent direct contact with sulfide electrolytes. These coatings establish stable interfaces through ion-conductive or fluorine-based SEI formation, dramatically improving capacity retention from 29% to over 60% after 100 cycles. Extending this approach to lithium–sulfur batteries, we uniformly coat commercial separators with ultra-thin polymer films via the iCVD process. This modification effectively mitigates the shuttle effect and dendrite formation—persistent challenges in Li–S systems. The engineered film exhibits excellent electrolyte wettability and enhances LiPS solubility, thereby reducing dissolution-related issues. Furthermore, its superior lithium-ion conductivity facilitates efficient ionic transport while reliably suppressing dendrite growth, enabling significantly improved electrochemical performance compared to conventional separators.

|

|

(2) Enhancing membrane performance via functional polymer thin-film modification

Separation processes are inevitable for high energy efficiency and environmental sustainability, impacting areas from clean water and air to pharmaceuticals, renewable fuels, and climate solutions. FTFL developes practical separation solutions for oil/water, microalgae, CO2 separation, OSN and PSA process by leveraging functional polymers and advanced surface engineering via iCVD. Our group has extensively explored crosslinked ultrathin polymer films, applying them to diverse separation challenges. Through precise iCVD control, we fabricated high-flux filters for continuous lipid recovery from microalgae, ultrathin organosiloxane nanolayers for record-high OSN selectivity in the 150–300 g mol⁻¹ range, and homogeneous copolymer coatings for tunable wettability-driven liquid separation.

| |

|

|

Together, these studies highlight the versatility of iCVD coatings as robust, scalable platforms for next-generation separation membranes. Also, we introduced hydrophobic polymer-coated membranes that selectively separate lipid products in biodiesel production, offering high flux, durability, and simplified downstream processing.

|

|

|

|

(3) Nano-adhesive with robustness and high adhesion for highly deformable device

Adhesives are increasingly recognized as essential components for achieving stable integration in advanced devices. iCVD-based adhesives enable the bonding of dissimilar substrates through physical adsorption without surface damage, while allowing the formation of sub-micron adhesive layers that are challenging to realize with solution processes. Pressure-sensitive adhesives (PSAs) produced via iCVD can be optimized by controlling the degree of crosslinking through thermal or photo-curing, showing strong potential for application in flexible electronic devices. In addition, forming interpenetrating polymer networks (IPNs) through vapor-phase deposition of adhesive layers provides new opportunities for strong bonding between diverse elastomeric substrates. With the advancement of foldable devices and reduction of its thickness, we have demonstrated high recovery of foldable device by engineering their thickness and rheological properties.

|

|

|

|

|

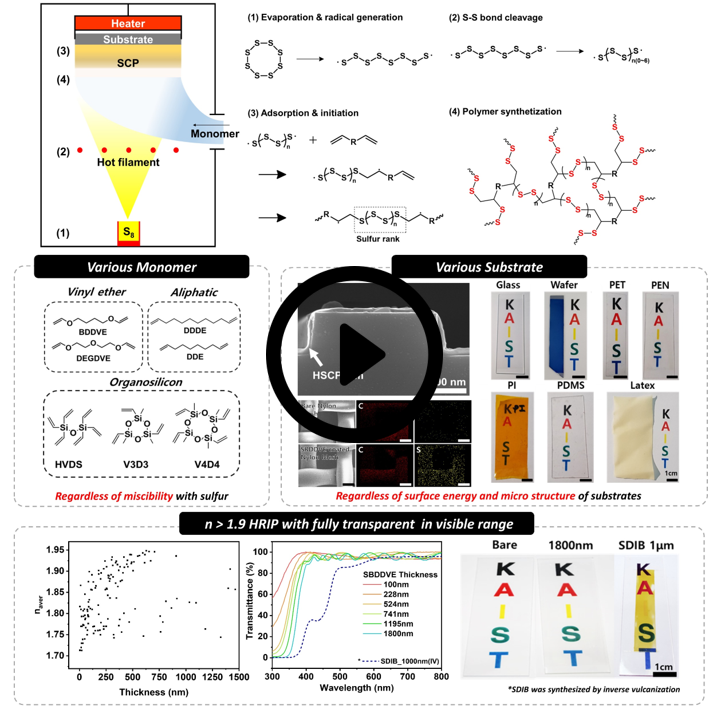

(4) High refractive index and transparent sulfur-containing polymers for optical devices

On the other hand, FTFL has devised a novel vapor-phase process, termed sulfur Chemical Vapor Deposition (sCVD). With a library of sulfur polymers, sCVD is applicable to high-performance optoelectronic devices, memory devices and batteries.

Unlike conventional methods, sulfur polymer films fabricated by sCVD exhibited high transparency in the visible region. In particular, the films show a refractive index exceeding 1.85, a glass transition temperature above 150 °C, and excellent IR transmission. The films also retain flexibility under repeated bending, demonstrating reliability for flexible platforms. Process control in sCVD enables tunable polymer structures tailored to device requirements. Nanoimprint Lithography (NIL) demonstrated precise patterning, highlighting potential for advanced optoelectronic architectures. Collectively, this study will pave the new way for next-generation optoelectronics.

| |

| Please click on the image to watch the video clip |

|

|

|

| |

|

|

| Lithium metal battery |

Separation process |

Sulfur chemical vapor deposition |

|

|

|

|

|

|

|